Operational excellence

Cutting-edge technology

Continuous improvement and perfectly coordinated production management set us apart.

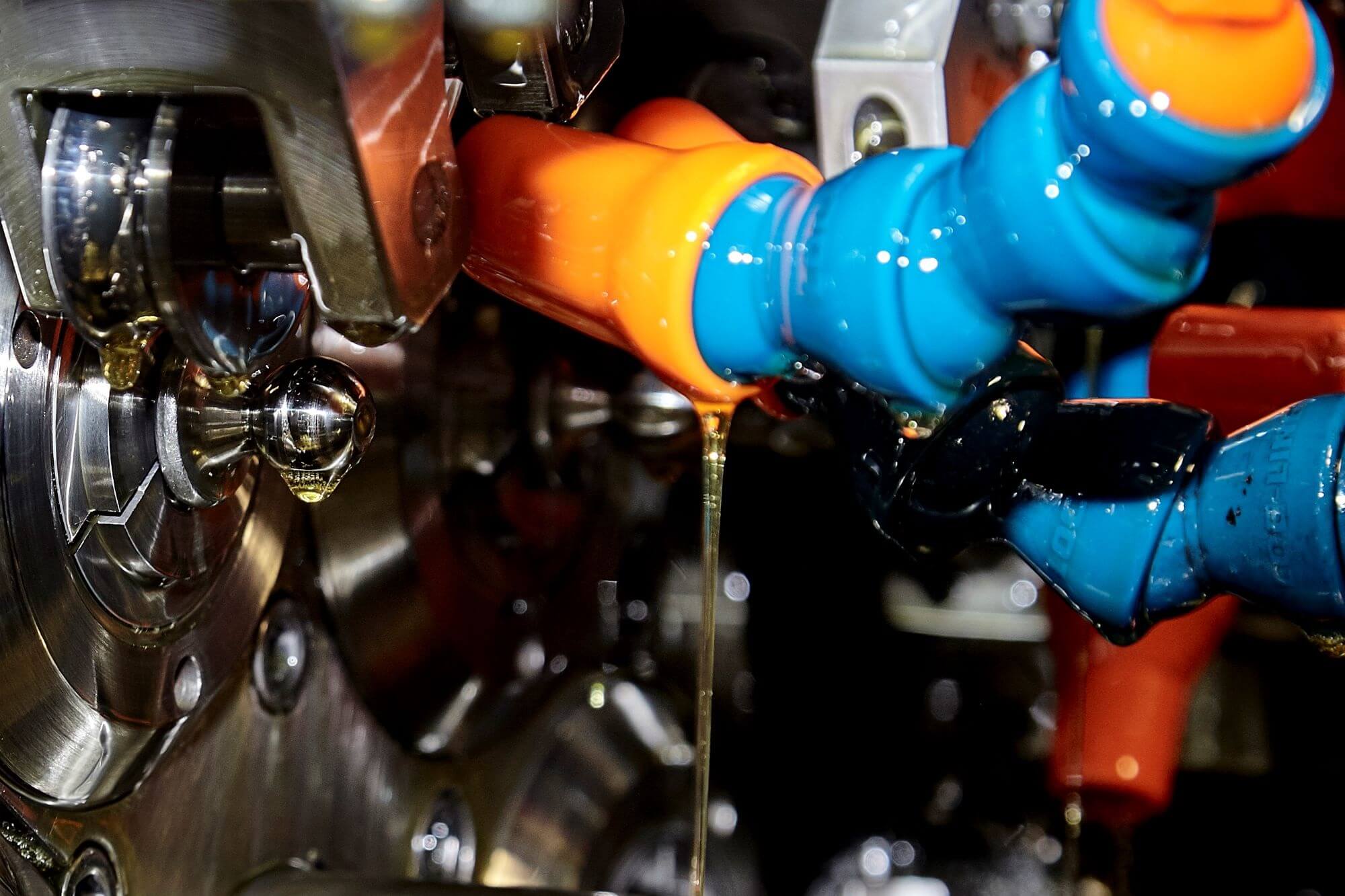

Cold forging technology is the company core process, and O.M.T. Fabbrica Viterie constantly works to maximize productivity with lean structures, high-performance processes and distinctive skills, in view of a strategic effectiveness and operational efficiency.

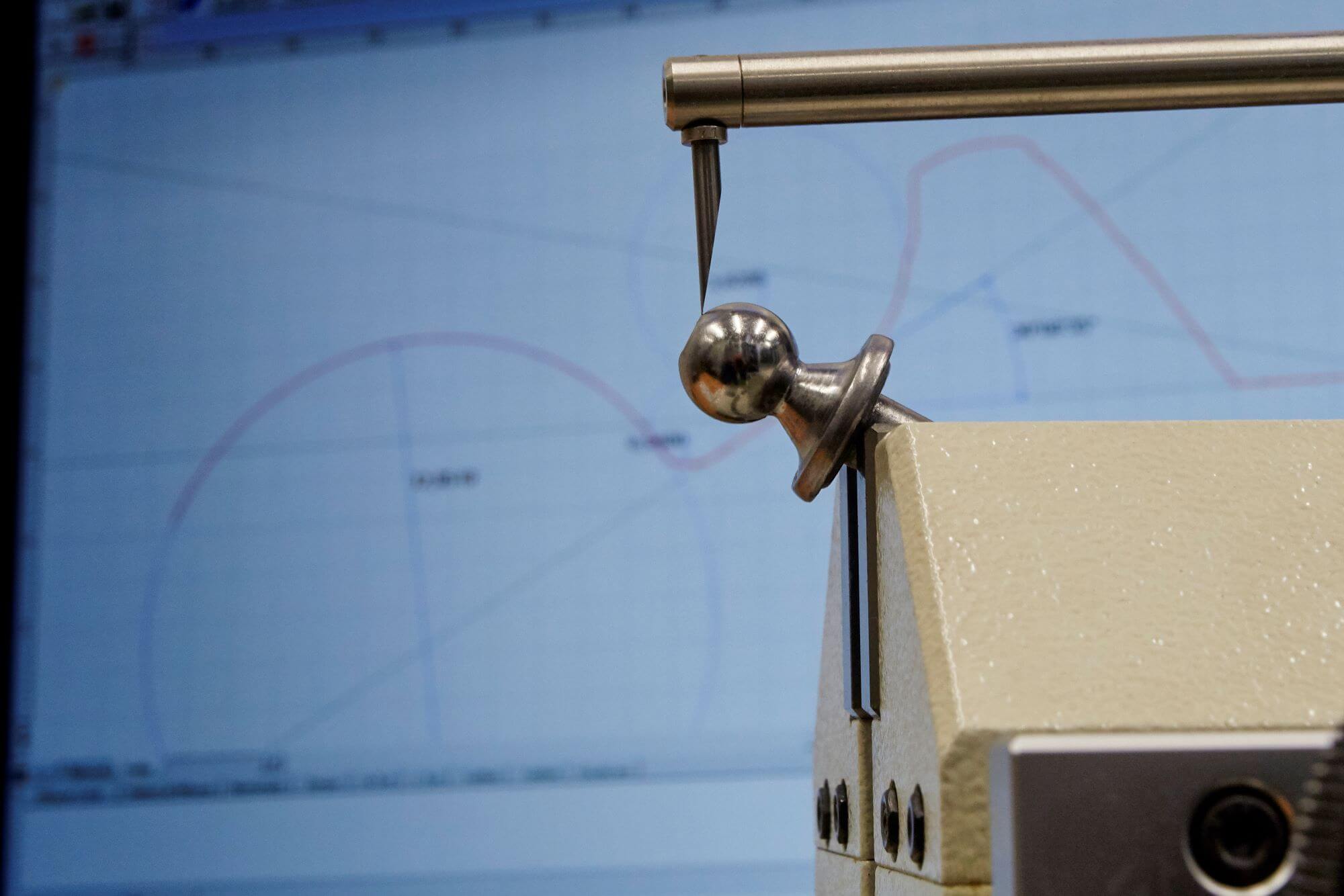

Each production parameter is constantly monitored and analyzed. The disciplined use of indicators is incorporated into a structured process to continuously improve performance and ensure maximum working accuracy.

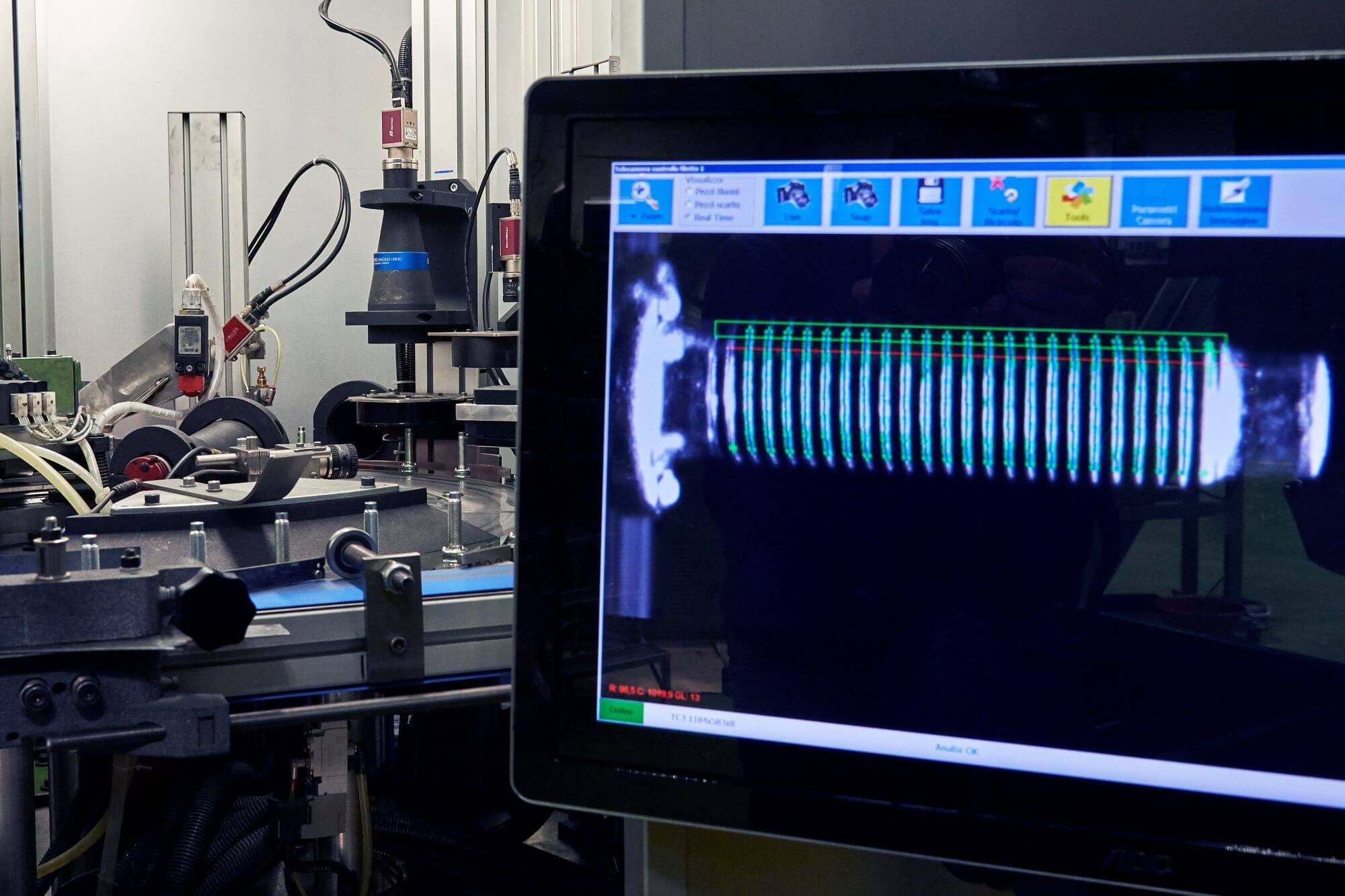

Moreover, the internal management of the forming process, of the secondary machining operations and the continuous investments in sorting machines, enable the complete control of the processes and increase the quality of the products.

Industry 4.0

To pursue excellence, we are committed to the future of technology.

To invest in industry 4.0 means to jointly reach the aims of flexibility, quality, productivity increase, reduction of waste, to achieve greater competitiveness in the future.

O.M.T. Fabbrica Viterie continuously invests in the enterprise digitalization for an innovation-oriented approach to processes and products, working on process automation and e-skills training. Actually, a route of digital integration of the business processes has been undertaken with the aim of managing all company activities in an integrated, effective and timely manner to reduce any kind of slowdown and corrective actions.

Results driven

O.M.T. defines and constantly updates new business strategies to reach the target of operational excellence.

Continuous improvement of work flows, preventive maintenance, personnel training, constant focus on quality, working environment and environmental impact are the foundation for the operational growth of the company.